By James Benington, Director

Seismic joints are one of those building elements that everyone knows are important, but few truly understand the complexities involved in getting them right.

Yes, they’re designed for earthquakes – that’s the obvious connection most people make. Here in New Zealand, where earthquakes are a genuine concern, these joints are critical. But thinking of them only as earthquake protection misses the bigger picture entirely.

These joints are working every single day. Managing thermal movement as buildings expand and contract. Handling wind loads that cause different sections to sway independently.

Accommodating the natural settling that happens in all structures over time. Whether it’s two buildings moving separately, a car park ramp flexing under load, or a bridge managing varying stresses, these movement joints – as they’re sometimes called – are constantly active, constantly being tested.

The critical part is that many of them need to remain completely watertight while doing all of this. Some of them also need to maintain a fire rating.

Also, with building regulations continuing to evolve, we’re seeing more remediation work, with new seismic joints being cut into existing buildings. The scope has increased significantly from previous standards, but with this complexity comes greater risk if the installation isn’t right.

The Issue Isn’t the Seismic Joint Itself

When we’re called to investigate water ingress problems around seismic joints, we rarely find that the wrong product was specified.

The designers and suppliers generally get this part right.

The science behind the performance requirements is well understood, and they work with architects and structural engineers to determine the forces, calculate the movement requirements, and specify compatible materials and fire ratings. There are hundreds of different versions of joints out there – metals and rubbers, foams and silicones – each designed for specific applications.

So by the time we do a final review of it on a drawing at tender, it’s typically well-designed.

One thing to note is that due to their precise nature, seismic joints are best measured on site prior to placing an order, or if they are ordered off the drawings, oversight of the builder must be high to ensure the joints are constructed to the correct tolerances. They are then manufactured specifically, which means there is a long lead time until they are available for installation.

Seismic joints are definitely an area where cost-cutting happens. Imitation products from overseas are specified because they come with the right paperwork and the right price. However, it’s also the workmanship and attention to detail that really catch installers out.

We know of several jobs where joints have been installed by others – same products we’ve used successfully in similar locations with no issues.

However, these joints were leaking. The installers thought the joints would be waterproof enough in those particular locations, but what they missed were the auxiliary products, the critical waterproofing detailing that actually makes the difference.

This largely comes down to a fundamental gap in expertise.

We’re waterproofers. Many other installers come from a carpentry background. They don’t understand the criticality around detailing, connections to other products, compatible materials, or how water actually behaves in these situations.

And, the other adjacent trades onsite tend to lack the required knowledge as well.

The Consequences Are Severe – and Expensive

We’ve seen water leak through a joint and travel down into critical spaces below. Leaking joints are not good for anyone – not the contractor, not the client, not the building users.

But the immediate damage is just the beginning.

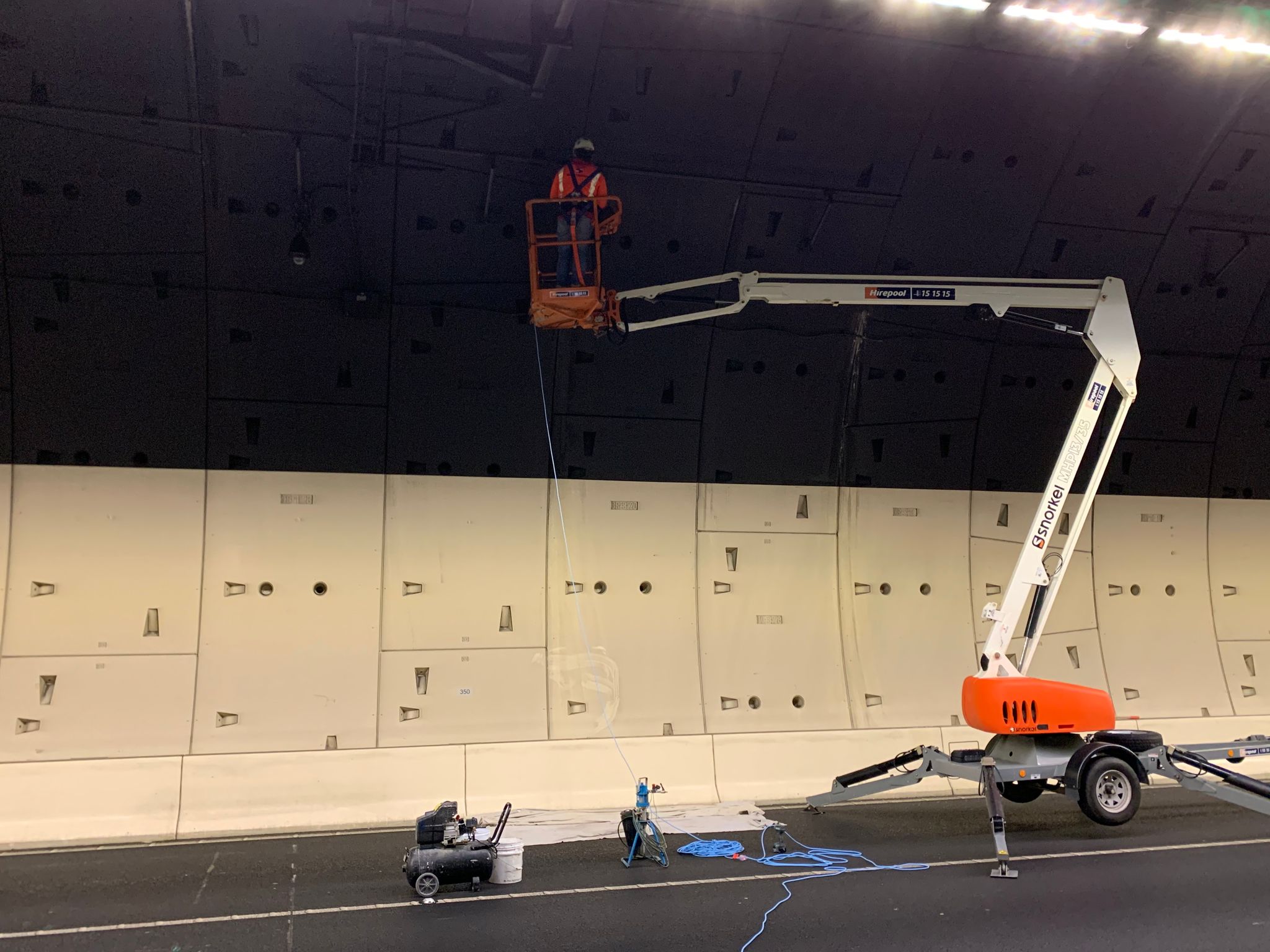

Fixing a failed seismic joint in a completed building means removing and replacing components in a live environment. On the side of a large-scale building, that means scaffolding, cranes, working nights and weekends to minimise disruption. The cost of fixing it properly often exceeds the original installation cost by multiples.

Getting it done right the first time is the real cost, time, and reputation saver.

The frustrating part? Most of the time when we’re getting called in, it’s because someone’s already made a complaint about water leaking somewhere. We’re there after the fact, when the damage is done and the expensive remediation begins.

Higher-quality joints installed properly will last far longer than low-quality joints installed poorly, or even high-quality joints installed poorly.

Quality Assurance That Actually Means Something

QA is only as good as the person doing it. When we review what passes for quality assurance from other contractors, it’s often just a box-ticking exercise.

At Sansom, we use the CONQA system with teams photographing and recording every detail. When something’s buried or installed on the side of a building, you can’t get back to check it later. It’s been hard work for us to get to this level of documentation, creating a comprehensive digital record that’s accessible to all stakeholders.

But documentation is just part of it. We flood joints completely with water to show they drain properly, and that they’re not leaking at any critical points. Yet even water testing can be meaningless if not done properly. It comes down to who’s holding the hose at the end of the day. If they don’t put it under enough stress to replicate what could actually happen in a storm, if they don’t think about where water might travel, then the test proves nothing.

The Right Person for the Job Requires the Right Expertise

We see smaller install crews doing seismic work, often supplementing their core teams with carpenters who aren’t busy. Since it isn’t their area of expertise, they don’t think about the work from a waterproofing perspective.

It’s a niche market – not every building needs extensive seismic joint work. Our 15 dedicated installers make us three times the size of most other companies’ seismic joint teams. But it’s not just about numbers.

At Sansom, internal training is a real focus. New applicators complete all relevant supplier training, then get paired with senior applicators for extensive on-the-job training. They learn what could go wrong, how to circumvent issues, how to identify what’s out of scope, and how to deal with complex situations.

Critically, our facade team does facade work all day, every day. They hone their skills constantly. We also pay by the hour, not by the metre – so our teams are incentivised to do quality work, not rush through as many metres as possible as others often do.

Sansom’s Approach to Seismic Joint Works

We’ve been here for 50 years. This matters more than you might think. Warranties are only meaningful while companies are around.

We also work with multiple seismic joint suppliers. Our independence means we can recommend the right solution for each project. Not every supplier has everything. Not all products suit every job. We choose our partners carefully, allowing us to match the right materials to the right application.

Our scale brings advantages. We handle car parks, bridges, new buildings and building upgrades, hospitals, and airports, to name a few. This variety, combined with training programs from multiple suppliers, keeps our teams current across all joint types.

Five years ago, we made a deliberate decision to bolster our facade division. We researched suppliers, attended training sessions, and invested in education. It’s quite technical now – not just a cover flashing and a bit of rubber in a joint anymore. For example, in hospitals and government buildings where return to service is critical, these sophisticated systems with counterweights and magnets require real skill and knowledge to install properly.

But perhaps our biggest advantage is that collectively across Sansom, our teams aren’t solely doing seismic work. They’re involved from breaking ground and digging foundations, through tanking, right to finishing roofs and internal coatings. We’re typically there from start to finish. This continuity – one contractor understanding how all these elements interact – can only benefit a project.

Get in touch to discuss your seismic joint requirements.